Dec 20, 2023

Automate Inventory Management: Streamline Business Operations.

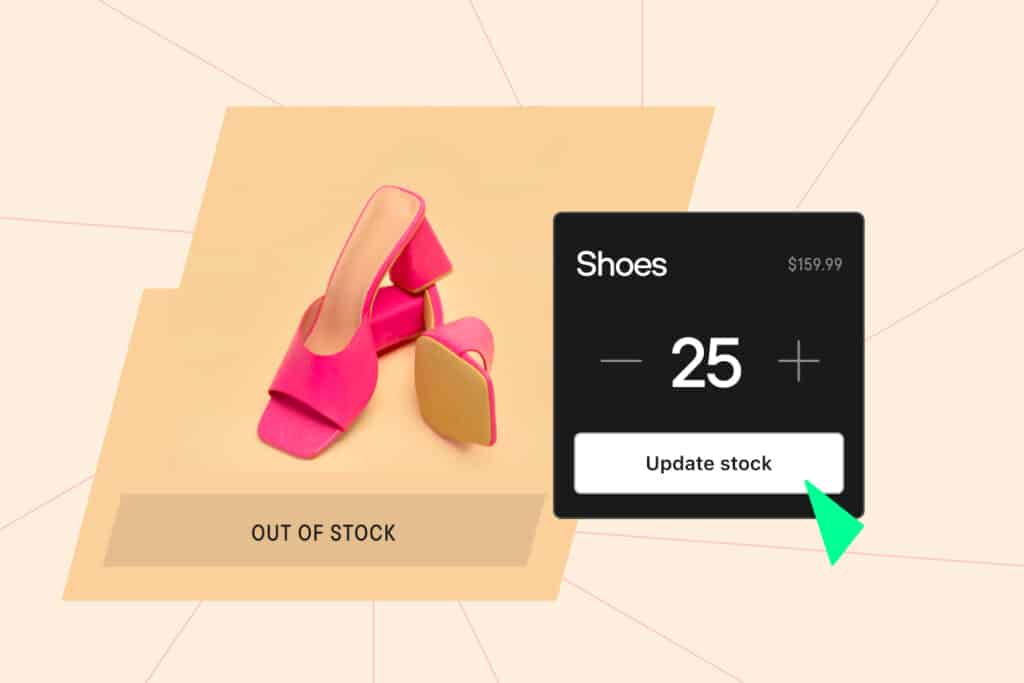

Are you drowning in spreadsheets and chasing stock levels? You can now automate your inventory process and eliminate the constraints of managing stock. This approach streamlines operations, reduces costs, and improves customer retention. In this guide, we will take you through the importance of effective inventory management, the benefits of automation and measuring its success.

Understanding the Basics of Inventory Management

Effective inventory management is essential for any business that deals with physical products. It involves tracking and controlling the flow of goods, ensuring that you have the right products in the right quantities at the right time. This includes forecasting demand, placing orders, receiving, storing, and fulfilling customer orders.

Proper inventory management is crucial for a successful business. It allows you to maintain a balance between having enough stock to meet customer demand and avoiding excess inventory. By managing your inventory, you can minimize stock outs, reduce carrying costs, and optimize cash flow. Studies show that automated inventory tools increased operational efficiency by up to 50%, cutting down manual labor and reducing human errors.

One of the key components of inventory management is demand forecasting. By accurately predicting customer demand, you can ensure that you have enough inventory on hand to meet orders without overstocking. This involves analyzing historical sales data, market trends, and other factors that may impact demand. With the help of advanced forecasting techniques and software, you can make informed decisions.

The Importance of Effective Inventory Management

Having a well-managed inventory is crucial for several reasons.

First and foremost, it allows you to meet customer demand while minimizing stockouts and excess inventory. This leads to improved customer satisfaction and retention. When customers can rely on your business to consistently have the products they need, they are more likely to return and recommend your business to others.

Additionally, effective inventory management helps you optimize cash flow by reducing inventory carrying costs and freeing up capital that can be invested in other areas of your business. Carrying costs include expenses such as storage, insurance, and depreciation. By keeping inventory levels in check and avoiding excess stock, you can minimize these costs and allocate resources to areas that can drive growth and profitability.

By analyzing inventory data, you can identify trends, spot opportunities for improvement, and make informed choices about pricing, promotions, and product assortment. This can give you a competitive edge in the market and help you stay ahead of your competitors.

Key Components of Inventory Management

Effective inventory management is a multifaceted process that involves several key components. These include demand forecasting, inventory optimization, order management, warehouse management, and fulfillment.

Inventory optimization is another critical aspect of inventory management. It involves determining the optimal inventory levels for each product based on factors such as lead time, demand variability, and desired service levels. By setting appropriate reorder points and safety stock levels, you can avoid stockouts and minimize excess inventory.

Order management is also an integral part of inventory management. It involves efficiently processing customer orders, tracking their status, and coordinating with suppliers to ensure timely delivery. By implementing an automated order management system, you can streamline this process and minimize errors and delays.

Warehouse management plays a crucial role in inventory management as well. It involves organizing and managing inventory within the warehouse, optimizing storage space, and ensuring efficient picking, packing, and shipping processes. By implementing barcode scanning and other technologies, you can improve accuracy and speed in warehouse operations.

Fulfillment is the final step in the inventory management process. It involves picking, packing, and shipping customer orders in a timely manner. By optimizing fulfillment processes and leveraging technology, such as order tracking and automated shipping labels, you can improve efficiency and customer satisfaction.

The Shift Towards Automation

In recent years, there has been a significant shift towards automating inventory management processes. This shift is driven by advancements in technology and the need for businesses to stay competitive in a rapidly changing market. By leveraging automation tools, businesses can improve accuracy, efficiency, and scalability in their inventory management practices.

One of the key drivers behind the shift towards automation in inventory management is the increasing complexity of supply chains. As businesses expand their operations globally, managing inventory across multiple locations becomes more challenging. Automation tools provide a centralized platform for businesses to track and manage inventory across different warehouses and distribution centers. This not only improves visibility but also enables businesses to optimize their inventory levels and reduce carrying costs.

Benefits of Automating Inventory Management

Automating your processes can bring several benefits to your business. Firstly, it helps reduce manual errors and eliminates time-consuming manual tasks, allowing your employees to focus on more strategic activities. Automation also enables you to streamline your order fulfillment process, leading to faster delivery times and improved customer satisfaction.

In addition, automation provides you with real-time insights into your inventory levels, allowing for more accurate demand forecasting and informed decision-making. By analyzing historical data and trends, businesses can identify patterns and make data-driven decisions regarding inventory replenishment, pricing strategies, and product assortment.

Moreover, automation tools can help businesses optimize their inventory levels by setting up reorder points and safety stock levels based on demand patterns and lead times. This ensures that businesses have the right amount of inventory at the right time, minimizing stock outs and excess inventory.

Furthermore, automation enables businesses to implement just-in-time (JIT) inventory management practices. JIT aims to reduce inventory holding costs by receiving goods from suppliers only when they are needed for production or sale. By automating the ordering process and integrating it with suppliers’ systems, businesses can achieve a seamless flow of goods and minimize inventory carrying costs.

Evaluating Your Current System

The first step in automating your inventory management is to evaluate your current system. This involves assessing your existing processes, identifying pain points, and understanding the specific areas that could benefit from automation. By conducting a thorough evaluation, you can determine the right automation tools and strategies to implement.

Choosing the Right Automation Tools

Once you have identified the areas that can benefit from automation, the next step is to choose the right tools. There are numerous software solutions available in the market, each with its own set of features and capabilities. It is important to assess your business requirements, budget, and scalability needs to select the tool that best fits your needs.

Implementing Automation

Once you have chosen the right automation tools, it’s time to implement them in your business. This involves migrating your existing data, configuring the software to align with your business processes, and training your employees on how to use the new system effectively. It is crucial to have a well-defined implementation plan to ensure a smooth transition and minimize disruptions to your daily operations.

Common Obstacles in Automating Inventory Management

One common obstacle in automating inventory management is resistance from employees who are accustomed to manual processes. Change management and proper training can help address this obstacle. Another challenge is integrating the new automation tools with existing systems and software. This requires careful planning and coordination to ensure data integrity and system compatibility.

Strategies to Overcome Automation Challenges

To overcome automation challenges, it is important to communicate the benefits of automation to your employees and provide the necessary training and support. Additionally, working closely with your automation vendors and internal IT team can help ensure a seamless integration and address any compatibility issues that may arise.

Measuring the Success of Your Automated Inventory Management

After implementing automated inventory management, it is crucial to measure its success and continuously improve your processes.

Key Performance Indicators for Inventory Management

There are several key performance indicators (KPIs) that you can use to measure the success of your automated inventory management. These include metrics such as inventory turnover rate, order fulfillment cycle time, stockout rate, and carrying cost of inventory. By regularly monitoring these KPIs, you can identify areas for improvement and make data-driven decisions to optimize your inventory management processes.

Continuous Improvement in Automation

Automated inventory management is not a one-time implementation. It requires continuous monitoring, evaluation, and improvement to stay aligned with your business goals and changing market conditions. By regularly reviewing your processes, analyzing data, and seeking feedback from stakeholders, you can identify opportunities for optimization and ensure that your inventory management remains efficient and effective.

By automating your inventory processes can help streamline your business operations and improve your overall efficiency. Continuous improvement and measurement of key performance indicators are crucial to ensure the long-term success and sustainability of your automated inventory management.

Automate eCommerce Processes.

Start today,

for free

Start a free trial of any of AMP’s tools today.